130t crane hire in Sydney

Sydney and Wollongong building sites can become impossible to navigate through when it comes to small access locations and difficult terrain. If you’re working in an area with tough terrain, you need a manoeuvrable 130t crane! We supply cranes with a high reach and manoeuvrability, perfect for your worksite. Hire our Liebherr LTM 1130-5.1 130t mobile crane today.

Why choose our 130t All-terrain crane?

Liebherr LTM 1130-5.1 Technical specifications

Specifications

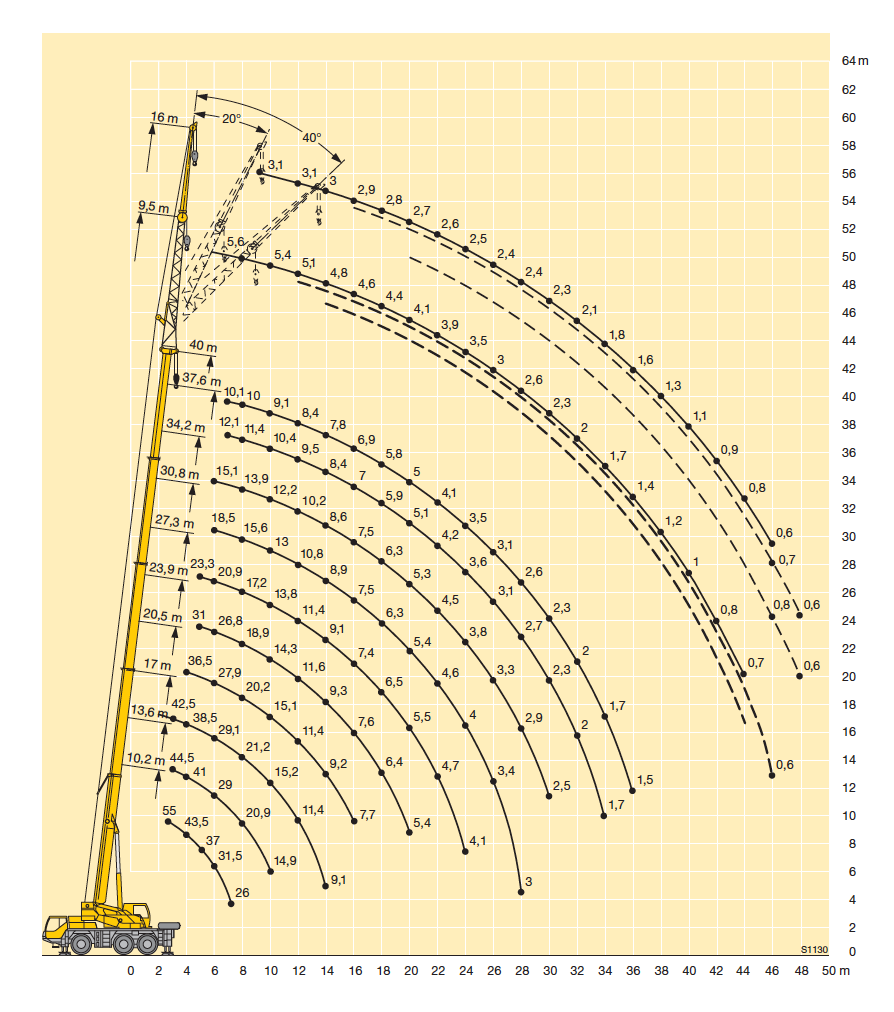

- Maximum load capacity: 130t

- Dimensions [LxWxH]: 14.80x2.75x4.00m

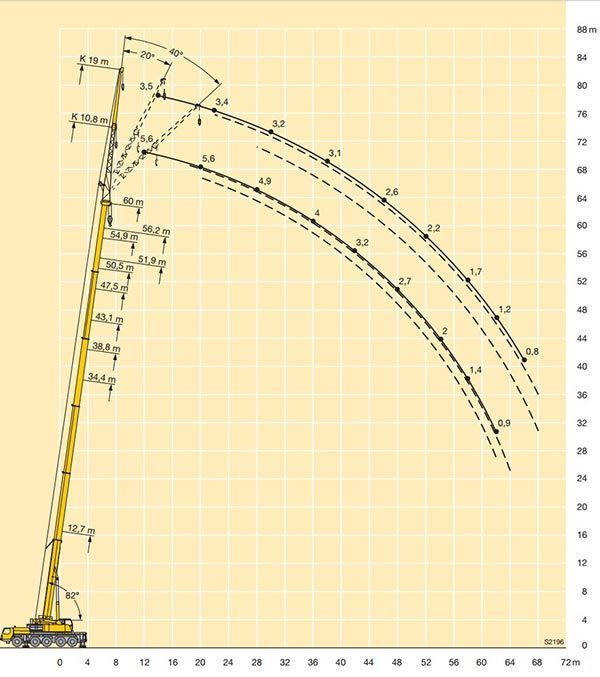

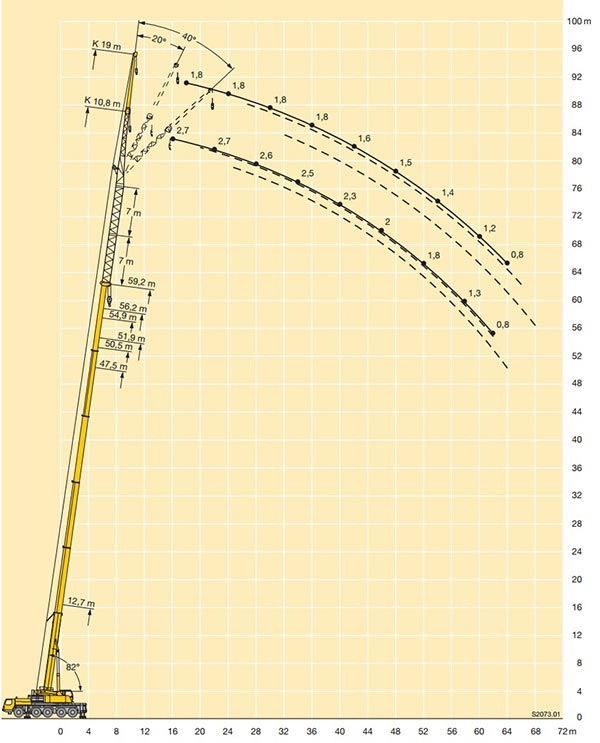

- Telescopic boom: 60m

- Maximum hoist height: 91m

- Maximum radius: 72m

- Number of axels: 5

- Drive engine capacity: 400kW

- Crane engine capacity: 129kW

- Maximum driving speed: 85km/h

- Maximum tip height: 95m

- Swing section length: 10.8m

- Stinger length: 8.2m

- Maximum luffing jib: 33M

- Maximum hook height: 91m

- Load torque: 4280kNm

- Maximum torque: 2516Nm

- Number of cylinders: 6

- Chassis length: 12.35m

- Turning circle radius: 10.39m

- Line pull: 88kN

- Maximum rope speed: 110m/min

Options

- Counterweight: up to 42t

- 2nd Winch

- Erection tip

- Additional ballast

- Telma eddy current brake

- 2 Hoist gear

Features

- Hydraulically adjustable jib

- Optimum lifting capacities with full and partial ballast

- Speed-dependent rear axle steering

- Pneumatic disc brakes with improved directional stability and brake pads

- Automated ZF AS-TRONIC gearbox

- 2-Stage transfer case

- Automatic 12-speed power shift system

- Dry coupling efficiency

- Compact design

- Hydro-pneumatic suspension

- Electro-hydraulically controlled rear axles for reduced tyre wear

- Centring cylinder for automatic straightening of rear axels in case of fault

- 2 Independent hydraulic circuits with wheel- and engine-driven hydraulic pump

- 2 Independent control computers

- Corrosion-resistant driver’s cab with tinted safety glass and electric windows

- Electronically adjustable outside mirrors

- Air-sprung driver’s seat with lumbar support

- BBT Bluetooth terminal, mobile control and display unit

- Electronic inclination display

- Fully automatic levelling by push button

- Engine start/stop and speed control

- Support area lighting with four integrated lights

- Heat- and noise-insulated interior cladding

- Floodlight

- Cab can be tilted 20 degrees backwards

- Centralised lubrication system

- Fully automatic telescoping system

- Oval boom profile gives high lateral stability

- Built-in planetary gearing and spring-loaded multi-disc brake

- Optimised fuel consumption with electronic engine management; Tier 3 compliant

- Diesel-hydraulic crane drive

- Open oil circuits with electric load sensing control

- LICCON Computer system allows electric/ electronic SPS crane control

- Integrated LML load moment limiter and work planner

- Colour monitor and touch displays integrated in armrests

Get rates

Our 130t cranes for hire are sure to provide you with the uplift you need for your project!

Our full range of cranes for hire

We have a range of cranes available for hire alongside our 130t All-terrain crane. These include:

13t Mobile slewing crane

View details16t Mobile slewing crane

View details50t Mobile slewing crane

View details20t Franna crane

View details25t Franna crane

View details28t Tidd (Franna type) crane

View details55t All-terrain crane

View details80t All-terrain crane

View details100t All-terrain crane

View details130t All-terrain crane

View detailsEnquire about our

130t All-terrain crane

If you’re anywhere near the Sydney, Wollongong, Wollondilly Shire, Blue Mountains and Southern Highlands areas, we can provide you with a quality 130t mobile crane. Give us a call now or fill out our online form to direct your questions to our team. We look forward to hearing from you!

Contact Us

We will get back to you as soon as possible.

Please try again later.